TrendComplex

I want to testthis solution

Selected features:

- ability to analyze trends in data entered manually or imported from spreadsheets, databases and external systems, e.g. ERP systems, SAP, MS SQL Server, Oracle, Excel, etc.;

- the ability to simultaneously monitor even thousands of parameters in a dashboard specially designed for this purpose;

- trending data from any area (stability tests, environmental monitoring, finished product, API, packaging materials, semi-finished product, process parameters, etc.);

- adaptive online data analysis algorithm which, depending on the specificity of the area (stability, microbiology, process parameters) and data distribution, selects and performs appropriate analyzes in real time;

- the ability to create your own analytical projects: you can select any fragment of data, various series, combine different series into one set and perform selected or all available analyzes for them, and view their results in the program interface or save them in the form of a report;

- configuring the alarm rule for unwanted events (OOS/OOL/OOT).

Our solution monitors process parameter values and product attributes in real time. For a large number of parameters, it monitors whether there are no phenomena such as: occurrence of a trend or change in its character (OOT), approaching warning limits or specification limits (OOS).

TrendComplex is a complex system that includes a repository of historical data, interfaces for downloading and entering data, automatic data analysis and visualization tools, an information database containing patterns and models to which parameter flows are compared, tools for convenient monitoring of any number of parameters and a system for alerting about undesirable events. Each implementation of TrendComplex is 100% adapted to the current situation and the needs and characteristics of the plant. Thanks to this, we ensure effective use of already existing data storage systems, application of trend analysis algorithms appropriate to the manufactured products and their specificity, and automation of existing procedures in the scope of data analysis and their periodic reporting.

HISTORICAL AND CURRENT DATA

The first element, which is not "visible" but which is the foundation, is a database. It stores historical data (needed to determine patterns, which are then one of the criteria for assessing the course of parameters), metadata (describing the meaning and characteristics of parameters), patterns and rules (with which new values will be compared) and continuously collected results of research on raw materials, semi-finished products, finished products, environment and production process parameters (which will be subject to monitoring and trend analysis). The database, apart from storing data, ensures their reliability and consistency and stores them in a system enabling the creation of analyses, summaries and reports in any cross-section.

MONITORING AND ALARMING

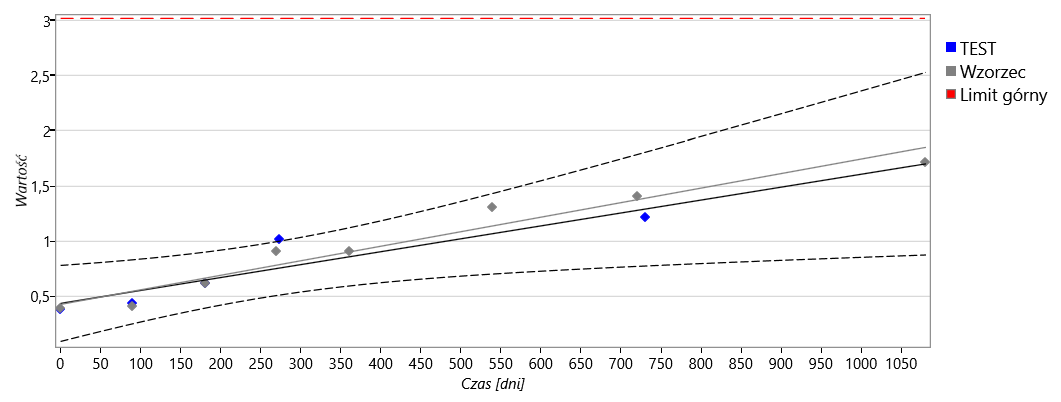

On the basis of new research results and process parameters collected on an ongoing basis, it is possible to automatically analyze them and create reports. In the first place, the person introducing subsequent measurements should receive feedback from time to time, evaluating the given result. For this purpose, the system automatically compares its value with the implemented rules and patterns (e. g. specific departure from the current trend, occurrence of an unusual trend, departure from the average, approach to warning limits or occurrence of a specific probability, or that the parameter will go beyond specifications in a specific time) and in case of such an event it immediately sends an appropriate message. In such a situation it is also important that such a person can easily (using automated analytical tools) see the results of the trend analysis for such a parameter and on this basis assess the situation.

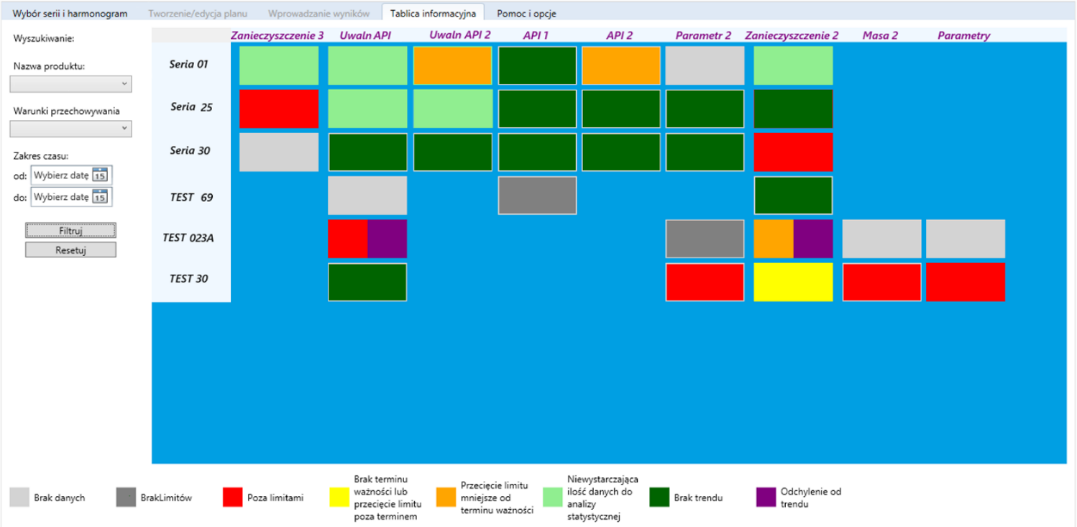

The key functionality of TrendComplex is the automatic monitoring by the system of incoming information, concerning even thousands of parameters and conveniently visualized current situation on a plant scale. For this purpose, we use a synthetic information board, which offers us a single graphical dashboard on which we can observe the current evaluation of individual parameters for all product series or for all parameters and products at the same time. The principle of operation is based on the visualisation (in the form of coloured tiles) of the results of a wide range of tests and assessments carried out automatically by the system. In this way we can find out whether, for example, all the tests were carried out on time and whether all the required results were entered, whether there is a risk of exceeding the limits by a given parameter, whether there is a trend in the data, whether the OOT was identified and on the basis of which criterion.

If, on the basis of new data, the system detects a situation defined as undesirable, a warning will be displayed on the information board and the persons responsible for these procedures will be informed about this event by e-mail.

In this way, it is possible not only to monitor the course of parameters and indicators on an ongoing basis, but also to predict and, as a result, prevent the occurrence of OOT/OOS or other worrying, unfavourable quality trends for the parameters of products, the process or the manufacturing environment. TrendComplex's complex solution is an effective way to meet the requirements of the new GMP release and to present a reliable, standards-compliant approach to trend analysis during the audit.

If you are interested in this solution, need additional information or want to see the program in live - please contact us.